Wedge Wire Filter Elemeents From Filtration Group

We represent Filtration group USA for their range of wedge wire filter elements.

These are ideally 20 and 25 micron filter elements used in automatic back was feed filters in

➤ Hydrotreaters

➤ Hydrocrackers

➤ Coker units.

The filter elements are used in housings of automatic backwash filter housings.

Some case studies

Filtration group has provided increased filtration area for a competitors filter system in a Hydrocraker

unit. The filtration surface area was increased by @ 80% only by changing the filter elements. This

significantly increased the time between backwashes. Same foot print, same housings and same valves were

used.

FG can also supply retrofit wedge wire filter elements for another competitors filter system (DHDS Unit)

that were using mesh type filter cartridges. The wedge wire filter elements had to be replaced frequently

requiring frequent opening of housings, waste of few volumes of filtration medium and disposal of clogged

filter cartridges.

Salient features

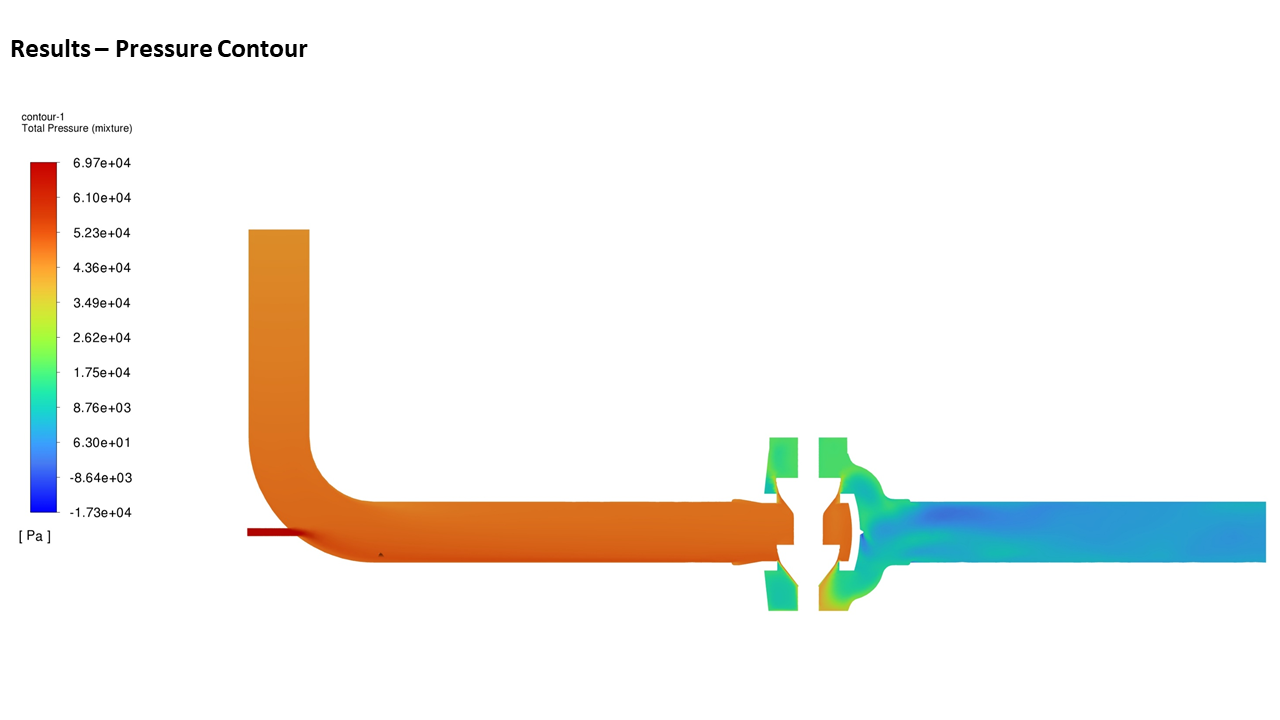

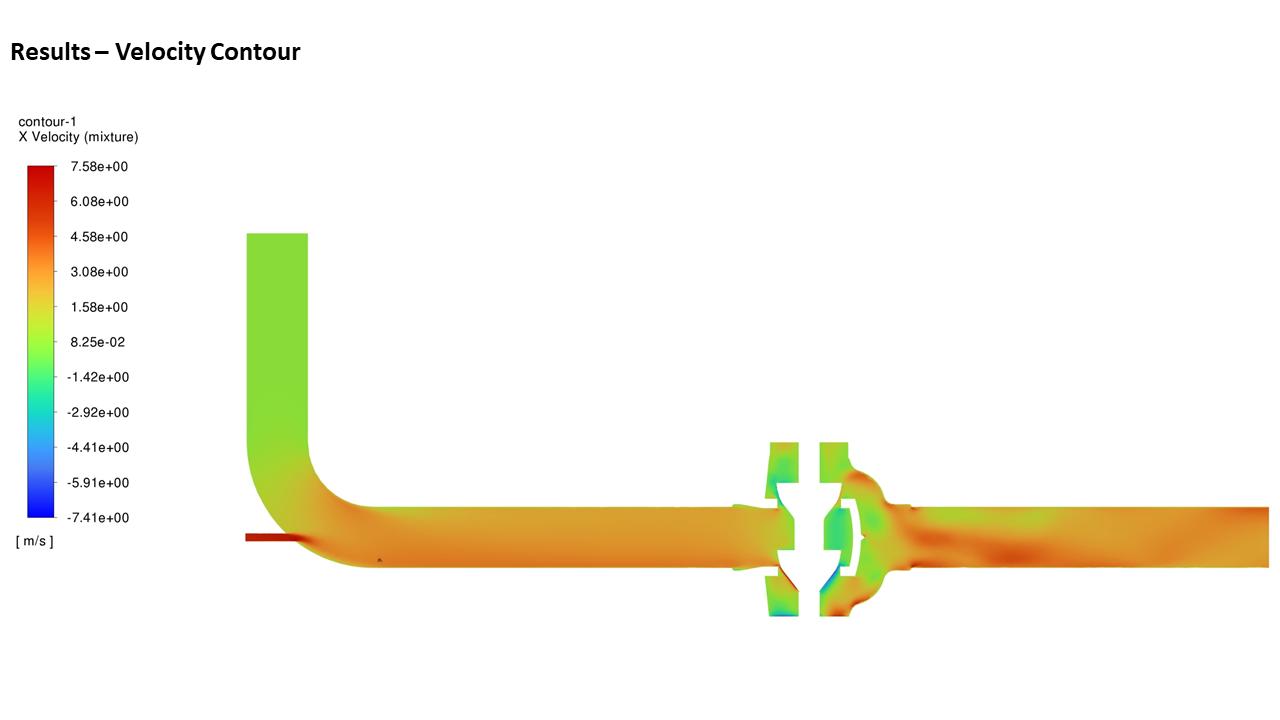

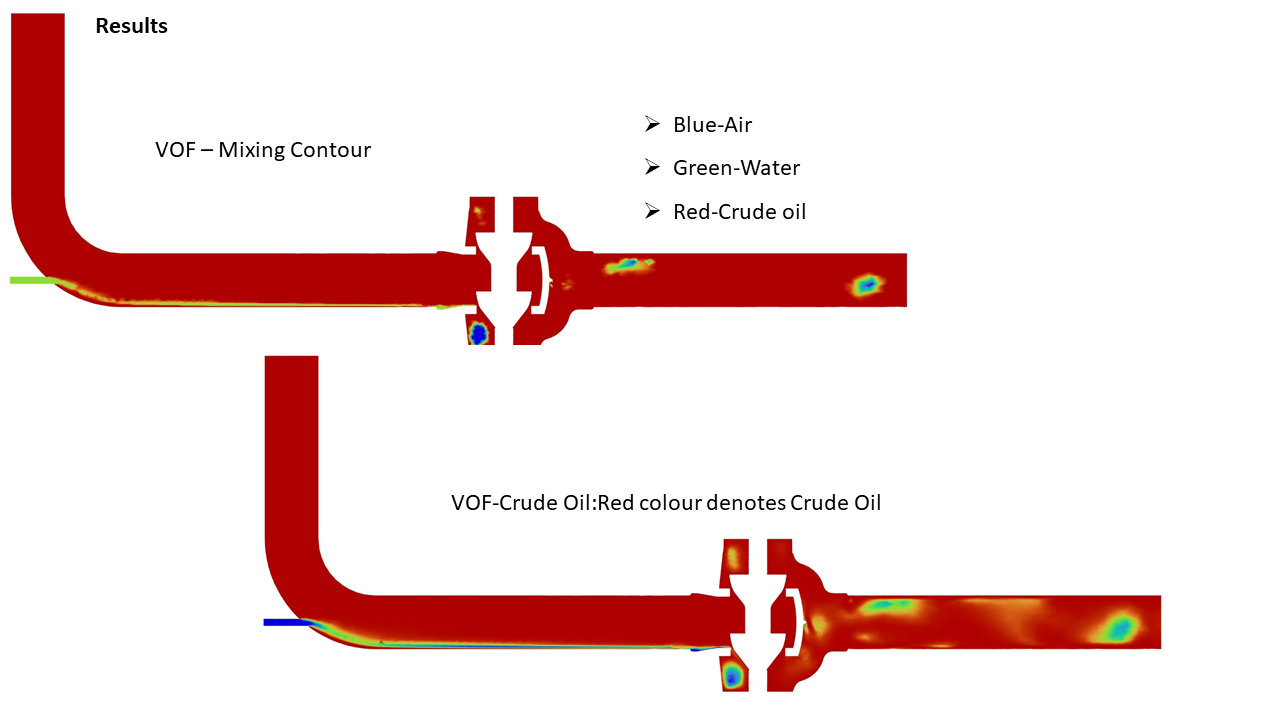

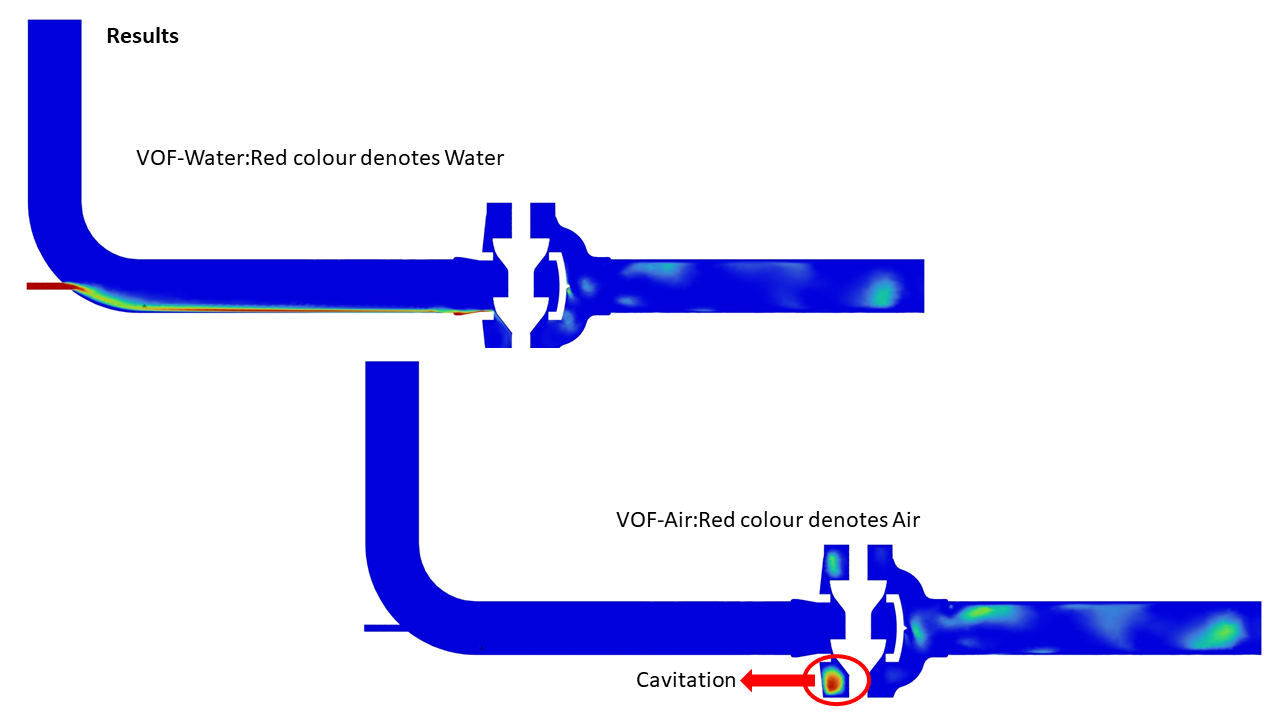

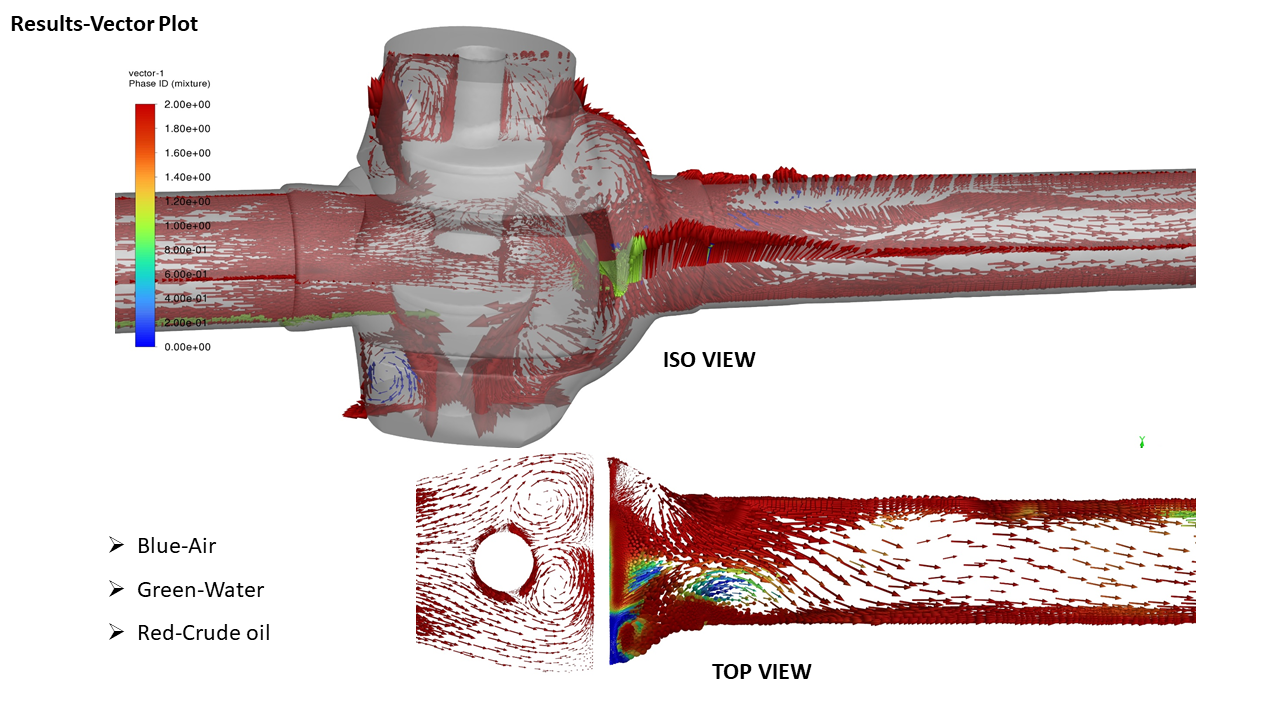

Filtration group does CFD study and has metered plates on the filter housings to ensure

most effective

backwash using a given backwash volume. Thereby ensuring clean filter elements before the start of

filtration cycle. This helps prolong time between backwashes and thereby lesser wastage for recycle and

reprocessing.

Our wedge wires are suitable for insitu steam backwash. Occasional manual steam backwash

helps in

dislodging asphaltenes (especially from coker streams in lower temperatures). This allows return of clean

delta P. The supply steam conditions, duration can be advised by FG.

This will also need some study to see downstream piping (valves) study to see if they can handle the steam

temperature.

Engineering support and advise on various mix of fluid streams to enhance time between backwashes

etc.

RUGGED ROBUST wedge wire elements that have higher design collapsible and burst pressure.